Responsible. Sustainable. Clean.

Eco-conscious gas abatement solutions for secure and sustainable waste management. Tailored for high safety and environmental standards.

Gas Abatement Solutions for Universal Abatement Applications

Find the right gas abatement for your application.

|

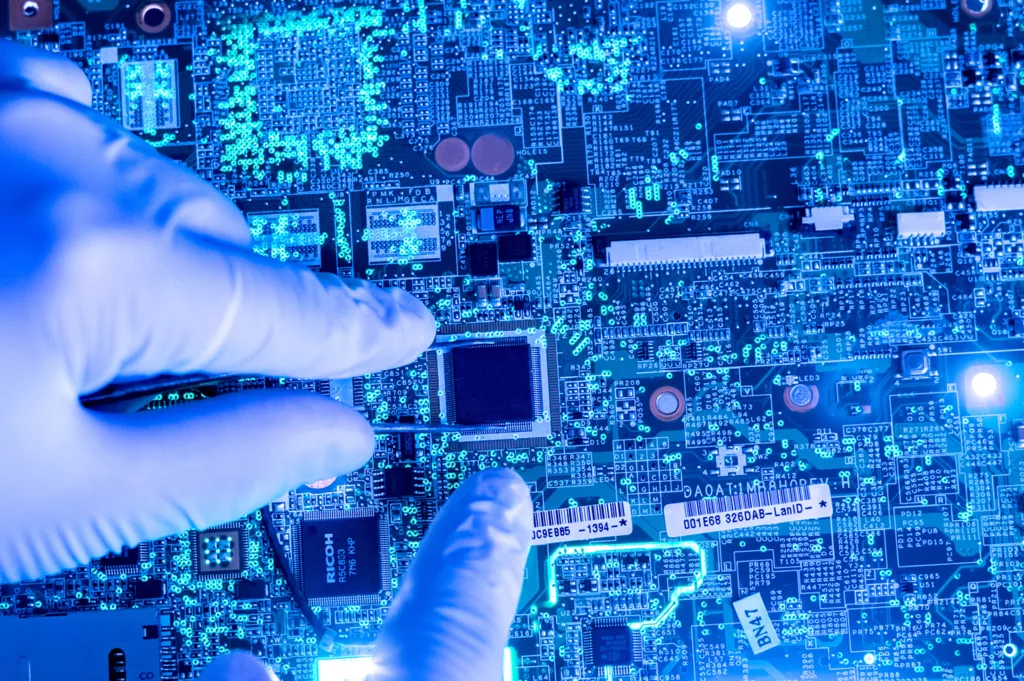

Ashing Atomic Layer Deposition (ALD) Chemical Vapor Deposition (CVD) Diffusion Epitaxy Etch Processes Ion Implant Lithography-Metrology Load Lock Vacuum Micro Machining (MEMS) Physical Vapor Deposition (PVD) Rapid Thermal Processing (RTP) Residual Gas Analysis Silicium Technology Sputtering Surface Analysis |

Coating Flat Panel Display (FDP) Industry Leak Detection Systems Machine Tooling Magnetic Media Medical Engineering Vacuum Drying |

Analytical Tools Electric Gravometrics Mass Spectrometres Microsopy Osmometrics XPS |

Biotechnology Elementary Particle Physics Nanotechnology Nuclear Fusion Particle Accelerator Plasma Research |

Atomic Layer Deposition (ALD) | LED Manufacturing |

Fluoroproducts Industrial Chemical Productions Oxidation of Pyrophoric Gases Special Chemistry |

|

| Semiconductors | General Vacuum | Analytical Instruments | R & D | Photovoltaic | LED | Chemical Industry | |

| G5 | |||||||

| G6 | |||||||

| TND | |||||||

| Dynox | |||||||

You can filter the components according to the industries.

Gas Abatement Solutions (4)

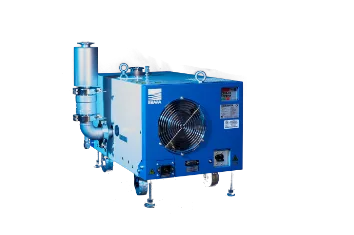

G5

Industries

G6

TND

Dynox

Industries

Explore Our Gas Abatement Systems

Advancing Industry Standards with Our Premier Gas Abatement Systems

Discover our comprehensive range of gas abatement systems, meticulously designed to meet the stringent demands of engineers across various industries. In this article, we will delve into the world of gas abatement systems, providing insights into what they are, their crucial role, different types, reliability, and the importance of selecting the right system for specific applications.

An Introduction to Our Gas Abatement System Range

Our gas abatement system range represents the pinnacle of engineering tailored to industrial requirements. These systems play an essential role in ensuring environmental compliance and workplace safety. Engineers rely on them for their efficient removal of hazardous gases and particulate matter, safeguarding both the environment and personnel.

Understanding Gas Abatement Systems and Their Crucial Role

Gas abatement systems are specialized equipment designed to capture, treat, and neutralize harmful gases emitted during industrial processes. These systems are indispensable for mitigating the impact of volatile organic compounds (VOCs), hazardous chemicals, and other pollutants on the environment and human health.

Types of Gas Abatement Systems and Their Applications

Our gas abatement system range encompasses various types, each tailored to specific industrial applications. Here are some key types and their uses:

Wet Scrubbers:

Wet scrubbers are highly effective at removing acidic and caustic gases. They are commonly used in semiconductor manufacturing and chemical processing to neutralize and capture harmful emissions.

Thermal Oxidizers:

Thermal oxidizers are ideal for high-temperature applications. They are frequently deployed in industries such as automotive manufacturing and pharmaceutical production to combust and eliminate volatile organic compounds.

Adsorption Systems:

Adsorption systems are versatile and find use in applications like the semiconductor industry, where they capture and remove hazardous gases through adsorption onto specialized media.

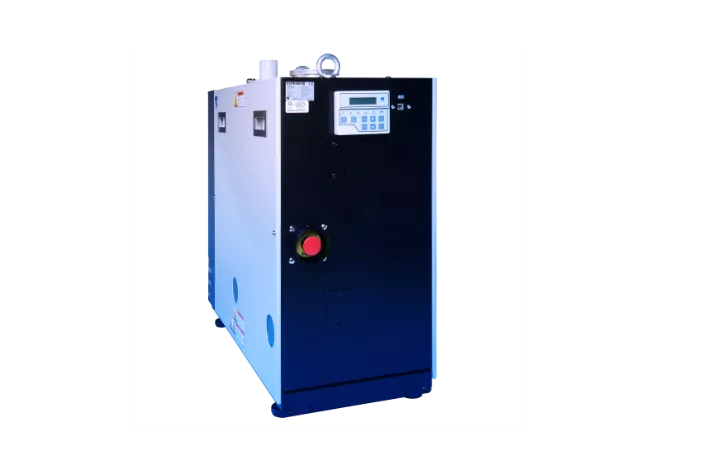

Building upon this array of solutions, we introduce the Dynox Gas Abatement Systems, engineered by EPME for top-tier sustainability and operational efficiency. Dynox’s innovative systems are distinctively designed to operate without the need for external gas or fuel oil inputs, utilizing only air for their process. This remarkable feature not only ensures compliance with the highest environmental standards but also offers significant cost savings by eliminating the need for fuel. The Dynox line is the epitome of our commitment to providing eco-friendly solutions without compromising performance.

Reliability, Performance, and Versatility

Our gas abatement systems, including the cutting-edge Dynox offerings engineered by EPME, are designed for reliability and outstanding performance. They function efficiently, ensuring the thorough removal of harmful gases and particulate matter, thereby reducing environmental impact. The versatility of these systems across a variety of industrial applications demonstrates their adaptability.

Choosing the Right Gas Abatement System

Selecting the proper gas abatement system is critical for environmental compliance and workplace safety. Whether you need the practicality of a Wet Scrubber, the high-temperature functionality of a Thermal Oxidizer, or the innovative and eco-friendly design of a Dynox system, our range has a product tailored to your specific requirements. Our gas abatement systems, including those engineered by EPME, embody efficiency, reliability, and versatility, ensuring adherence to strict environmental regulations.